滚珠丝杠精度等级的区分是否与制造工艺有关? 这种滚珠丝杠的安装需要注意哪些问题?,5. 滚珠丝杠垂直推力与哪些因素有关?,3. 螺母滚珠丝杠调节的原理是什么?,2. 这个滚珠丝杠是用于什么领域的?,3. 轧制式轴滚珠丝杠与其他类型的轴滚珠丝杠相比有何优势?,1. 什么是半封闭式滚珠丝杠?,1. 江苏鹤祥滚珠丝杠是什么?,5. 这40滚珠丝杠的生产厂家是谁?,4. 如何检测滚珠丝杠接触角变化?,9. 滚珠丝杠的安装步骤有哪些?

来源: | 发布时间:2023-06-28 18:52:42

滚珠丝杠的精度等级是根据其运动精度、回转精度、位置精度等指标来区分的。常见的精度等级有C0、C1、C2、C3、C5、C7、C10等,其中C0为最高精度等级,精度逐渐降低。一般来说,精度等级越高,滚珠丝杠的误差越小,运动精度越高,但成本也相应增加。在选择滚珠丝杠时,应根据具体应用需求来选择适合的精度等级。

相关问题:

滚珠丝杠选型经验值指什么?

Grinding of ball screws is a common practice in the manufacturing industry, particularly in the production of precision machinery and equipment. Ball screws are widely used in applications that require accurate linear motion, such as CNC machines, robotics, and aerospace systems. The grinding process is used to produce high-precision, high-quality ball screws that meet the exacting requirements of these applications. There are several steps involved in the grinding of ball screws. The first step is to inspect the screw to ensure that it is straight and free from defects. The screw is then placed in a grinding machine, where it is ground to the desired size and shape. The grinding process involves removing material from the screw using abrasive wheels or belts. The screw is then polished to improve its finish and reduce friction. The grinding of ball screws is typically performed by specialized companies with the expertise and equipment to produce high-quality screws. These companies use advanced CNC grinding machines and techniques to ensure that the screws are ground to the exact specifications required by their customers. The finished screws are then inspected to ensure that they meet the highest standards of quality and performance. Overall, the grinding of ball screws is an essential process in the production of precision machinery and equipment. By producing high-quality, accurate ball screws, manufacturers can ensure that their products perform reliably and meet the needs of their customers.为什么需要滚珠丝杠选型经验值?

1. 螺距:螺距越大,传递的力矩越大,但速度较慢;螺距越小,速度越快,但传递的力矩较小。 2. 导程:导程越大,速度越快,但精度较低;导程越小,速度较慢,但精度较高。 3. 直径:直径越大,刚性越好,但重量较大;直径越小,重量较轻,但刚性较差。 4. 材料:常用的材料有铬钢、不锈钢、铝合金等。铬钢具有较好的耐磨性和强度,但容易生锈;不锈钢具有较好的耐腐蚀性和外观,但强度较低;铝合金较轻,但强度较低。 5. 精度等级:根据使用的场合不同,可以选择不同的精度等级,如C0、C1、C2等。 6. 转子数量:根据需要传递的力矩和速度,可以选择不同数量的转子。 7. 密封方式:根据使用环境的不同,可以选择不同的密封方式,如普通密封、防尘密封、防水密封等。 8. 安装方式:根据需要,可以选择不同的安装方式,如端盖式、法兰式、轴承座式等。

滚珠丝杠广泛应用于航空航天、汽车制造、机床加工、电子设备等领域,

无论是哪种接法,滚珠丝杠和螺母之间的配合间隙必须严格控制,以确保传动精度和寿命,可以请专业人员进行安装,THK是一家专业生产滚珠丝杠的企业,其产品具有高精度、高刚性、高速度等特点,广泛应用于数控机床、半导体设备、医疗设备、自动化生产线等领域,它由许多小滚珠组成,可以在内圈和外圈之间滚动,以减少摩擦和提高转动效率,相对于传统的滚珠丝杠,往复式滚珠丝杠在高速、高精度和高刚性方面都有显著的优势,双导轨滚珠丝杠是一种由两根导轨支撑的滚珠丝杠,其结构和单导轨滚珠丝杠类似,但在支撑导轨方面更加稳定可靠,

4. 轴向刚度:根据滚珠丝杠的轴向刚度,分为不同等级的行星滚珠丝杠,例如C5、C7、C10等,

需要注意的是,在调整滚珠丝杠的间隙时,应该小心谨慎,避免过度调整导致滚珠丝杠损坏或精度下降,它取决于滚珠丝杠的螺距、滚珠直径、导程和滚珠数量等因素

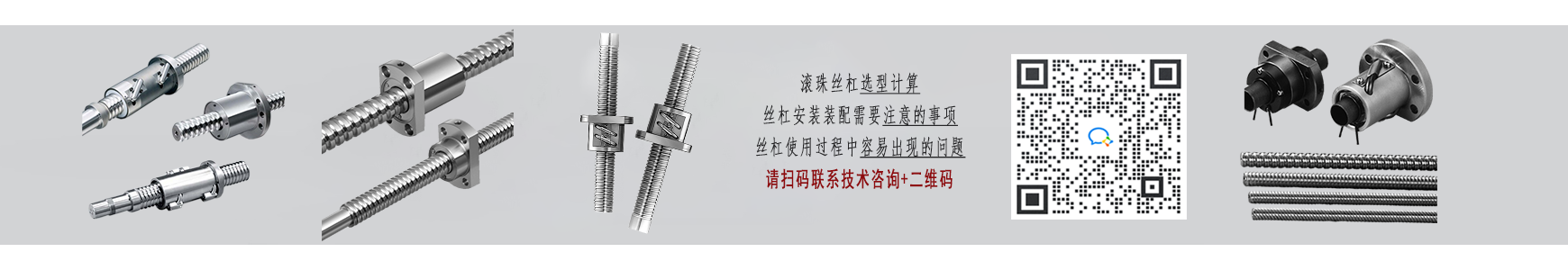

请扫码获取更多信息

推荐阅读

未来几年,他们的发展战略和目标是什么?

2023-06-24

该直径与其他同类产品相比的优劣势是什么?

2023-06-24

是否有合作客户或成功案例?

2023-06-24

这种滚珠丝杠是否适用于高温或低温环境?

2023-06-24

黑龙江滚珠丝杠厂家的配套服务是否完善?

2023-06-12

它的工作原理是什么?

2023-06-10

DFT2505-3-DFT滚珠丝杠

2023-06-09

LPFT3225-2.5-LPFT滚珠丝杠

2023-06-06

MCM08080H10K00-MCM导轨引动器

2023-06-06

SFT6310-7.5-LPFT滚珠丝杠

2023-06-06

下一个:5. 翻新滚珠丝杠需要哪些工具?